FREE SHIPPING AUSTRALIA WIDE

Free shipping on all retail orders

AUSTRALIAN OWNED & OPERATED

Licenced WaterMark Supplier

Twistloc® 12mm Tube x 1/2" BSP Female Adaptor SPSU6734BM WaterMark Certified (10-102WM)

- Simple and Easy to install.

- Secure connection indicator helps confirm leak-free joints.

- Easy verification of coupling (lock/unlock) status, even from a distance.

- Removable and reusable without damage to plumbing or fittings.

- Lightweight for easy handling.

- Strong connection suitable for heating systems.

- Product traceability - code printed on the product to track manufacturing quality control.

- Flame-free, no need for a blowtorch.

- No corrosion or mineral build-up.

- Low heat diffusion ensures safe surface temperature.

- More resistant to bursting under freezing temperatures.

- No lead, non-toxic.

Twistloc®

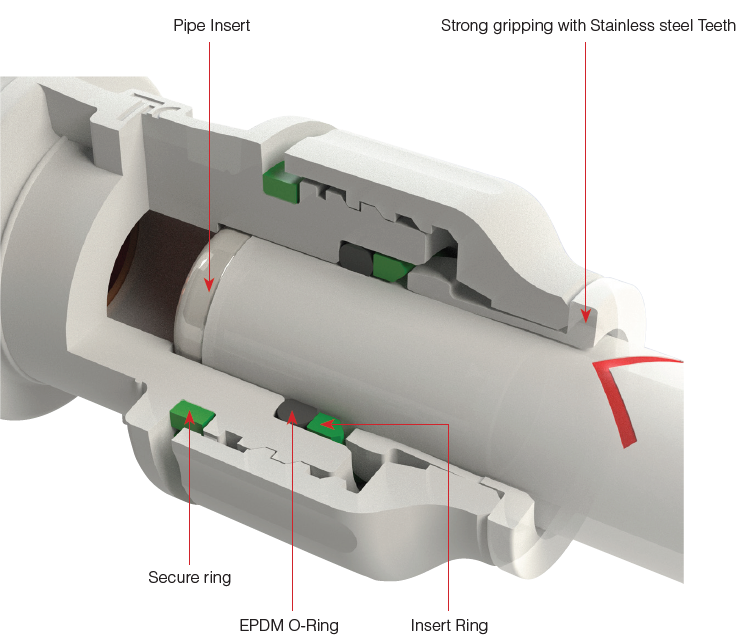

Twistloc® push-in fittings incorporate advanced technology, providing enhanced reliability and effectiveness in comparison to conventional fittings and valves. These innovative fittings guarantee long-lasting performance, granting you peace of mind during installation. By employing visual color connections, all plastic fittings and valves ensure secure connections. Twistloc® products carry certifications for PEX, PB, Copper, and cPVC pipe, enabling effortless combination of different pipe types for repairs or new installations. With straightforward installation procedures, our products significantly reduce labor time, thereby facilitating efficient workflow.

Twistloc® Features

Twistloc® products introduce a convenient and reliable push-fit plumbing system that combines pushfit and twist locking technologies. This unique design ensures a secure and leak-free joint, offering complete peace of mind. Suitable for plumbing, local/home hot water supply, and heating systems, Twistloc® utilizes a pressure and combination system, making it an ideal twist and lock solution. Our products have undergone rigorous testing and received approvals from WRAS, Kitemarked to BS 7291 Parts 1, 2, and 3 Class S, cUPC, NSF, Watermarked to AS 4176.3, and ACS. Manufactured to ISO 9001 BSI standard, they comply with the requirements of central local/home heating and water supply systems. Extensive tests have demonstrated the exceptional resistance of Twistloc® products to temperature and pressure beyond normal operational ranges. The patented secure connection indicator ensures peace of mind by visibly confirming proper joint connection—once the green band is no longer visible, you can be certain of a secure joint. This indicator simplifies installations, enhancing both safety and ease of use. To ensure proper installation, it is crucial to adhere to the correct plumbing regulations. For detailed fitting instructions, please refer to our installation guide.

Usage and Installation

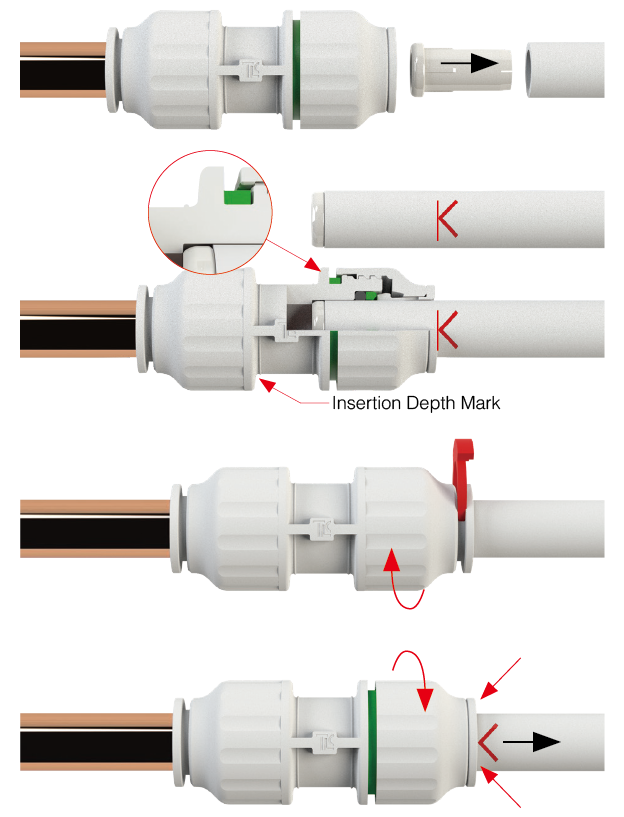

Prepare the Pipe:

Ensure the pipe end is free from score marks. Cut the pipe square using a tube cutting device. To prevent damage to the fitting, remove and burs from the end of the tubing/pipe. When using tube inserts, a twisting motion will aid the insertion.

To Lock the Pipe Connection:

These instructions relate to the installation of Twistloc® fittings for copper, PB, PEX and cPVC pipes.

Please note that it is the installer’s responsibility to ensure that Twistloc® fittings, pipework and other components are appropriate for the intended applications, and that products are installed in accordance with the installation instructions and local plumbing codes.

No information in this publication is intended to create any warranty beyond the SNC product warranty applicable to the plumbing system.

Installing push-fit products:

Before you start, inspect the pipe. Ensure there are no scratches, gouges or any form of damage or deformation on the pipe. It should also be free from dirt and grease that may affect the seal.

Pay close attention to the first inch (25.4mm) from the cut ends. Damage or foreign substances in this area may cause leakage problems. If there are any concerns, cut the affected pipe end to a clean and undamaged point.

Don’t use any coarse materials to clean the outside surface of either plastic or copper pipes as this could affect the seal and result in leakage.

Ensure fittings and pipes are always kept clean by keeping them in the packaging provided - don’t empty products onto the floor.

Never insert your finger into the fitting as you risk being cut by the metal ‘grip teeth’ inside the fitting.

To Disconnect:

Make sure that the system is de-pressurised. Unlock fitting by twisting until coloured ring is visible. Press collect squarely against the face of the fitting. With the collet depressed, pull on the pipe to remove it from the fitting.

CAUTION

Do not apply any impact force to Twistloc® fittings.

Twistloc® fittings are plastic materials and should not be treated the same as metals.

Twistloc® fittings may melt, crack or distort if exposed to open flames or excessive heat.

Do not use pipe sealant, thread sealants or Teflon® paste in order to seal threaded fittings. All the connections to Twistloc® fittings are either a mechanical compression type, or seal with a rubber gasket and do not require any other forms of sealant. Do not insert fingers into Twistloc® fittings as the stainless steel teeth may cause injury.

If PEX pipe is used, then a tube support liner must be used also. The tube support liner acts as an internal support for the end of the pipe.

Twistloc® fittings should not be used for gas, fuel oil or compressed air applications.

DO NOT allow contact with any chemical or foreign substance; paint stripers, solder flux, Acid based descalents or chemical.

Twistloc® fittings are not suitable for buried installation.

All Twistloc® fittings and related products should be selected, installed, used and maintained in accordance with these Technical Specifications.

When cutting pipe, ensure that the ends are cut square and are free of burrs.

Ensure that there are no scratches, gouges or any form of damage on the circumference of the pipe within 1 in. (25.4mm) of the cut end. Damage in this area may cause leakage. Check the fitting for any signs of damage or foreign objects.

Do not use a damaged or scored pipe.

- Do not leave burrs on the pipe.

- Ensure that the pipe is pushed into the fitting fully and is engaged properly in accordance with the instructions.

* If the pipe is not fully inserted, the connection cannot be properly sealed even if the fitting is coupled.

* If these installation guidelines conflict or are inconsistent with local building or plumbing codes, any codes applicable to parallel plumbing systems shall prevail.

Do not use a hacksaw to cut a pipe. Do not leave burrs on the pipe.

Ensure that the pipe is pushed into the fitting fully and is engaged properly in accordance with Twistloc® instructions.

If the pipe is not fully inserted, the connection cannot be properly sealed even the fitting is coupled.

You must push in the pipe passing the collets (gripper) and the O-ring inside the fitting.

When a connection has to be disassembled and reused, ensure the pipe has no damage around the circumference within 1" (25.4mm) of the end. Inspect the tube and fitting for any signs of damage and ensure they are free of foreign materials. The connection can then be reassembled.

For plastic pipes:

- Always use an appropriate pipe cutting tool such as plastic pipe shears to cut plastic pipes. Never use a hacksaw as this could cause damage.

For copper pipes:

- Use a pipe cutting wheel or pipe slice.

Fittings & Valves Performance

| Working Temperatures and Pressures | |||

|---|---|---|---|

| NO. | Usual Temp | Max Temp | Pressures |

| Cold Water | 20˚C | 20˚C | 12 bar |

| Hot Water | 65˚C | 95˚C | 6 bar |

| Central Heating | 82˚C | * 114˚C | 3 bar |

Maximum Torque Figures

The Maximum torque values for threads used on Twistloc® products are as follows

| Thread | Size | Maximum torque |

|---|---|---|

| Plastic | 1/2″ | 3.5Nm |

| 3/4″ | 4Nm | |

| 1″ | 5Nm |

*1Nm=8.85Ibf·in/1Ibf·in=0.01kgf·m

Return Policy

Due to the nature of the products we sell, a strict return policy is in place. We work with food grade certified materials that must be un-opened and un-used as to be able to be re-sold.

You may receive a refund or credit of equal amount, less the restocking fee if applicable and any other deductions that are relevant.

- Wrongly purchased items may be returned for a merchandise credit, this applies for but not limited to: Wrong size, wrong system etc.

- 30 Day return Policy: Returns will not be accepted without prior approval or after 30 days of invoice date.

- All returns will incur a 17.5% restocking fee or cost to send the item to you whichever greater. FSA may use discretion to determine the restocking fee.

- Any damages (minor, that can be repaired) will incur a fee which will be deducted from the total refund which will be equal to the cost of the replacement

parts (List Price) and labour charge (if applicable) to repair the system(s). This will be separate to the restocking fee. - Any damage considered to be major and not feasible for repair may be refused and the return request will be void. The customer will be responsible for the return freight or disposal of the damaged unit.

- Return shipping is to be paid by the buyer to the address provided. It is recommended that the customer applies transit warranty to the return freight in case of damage.

- Any damages to the system that were not reported to FSA within 48 business hours of receipted delivery are not covered under our transit warranty.

- Should the item appear faulty or doesn’t work how described, the unit/item must be returned for testing (if requested), the return postage paid by the buyer. If the unit/item is deemed to be faulty, compensation will be provided for the postage cost (Proof of cost required). If the unit/item is deemed to be in working order and as described, the buyer will responsible for return postage.

If you have any questions about our return policy, please contact us before purchase. This will also help to ensure you purchase the correct product that suits your requirements.