Reverse Osmosis Water Filter 5 Micron Pre Filters (6 Month Replacement Pack) 10" x 2.5" (GT2-2K + GT4-7CTO)

This is the standard set of pre-filters for all of the following Undersink Reverse Osmosis systems:

Showroom open Monday - Friday 8am - 430pm excluding Public Holidays - Card Payments Only in Store - No Surcharge

Free shipping on all retail orders

Licenced WaterMark Supplier

| Select | Quantity | Discount | Price per piece | |

| 2-9 | 17% | 0 | $29.75 | |

| 10+ | 44% | 1 | $19.95 |

This is the standard set of pre-filters for all of the following Undersink Reverse Osmosis systems:

The first stage is a 5 Micron (uM) Sediment filter composed of 100% melt-blown polypropylene fibre. This cartridge helps to help protect the carbon pre-filters and reverse osmosis membrane from physical damage caused by particulate matter such as sand, dirt, silt, plant spores, and pollen. Physical contaminants such as these (which can surprisingly be found in most municipal water supplies), tend to clog up filter system components causing reduced water flow, lower osmotic pressure, diminished filtration efficiency, and ultimately, inferior water quality.

The second stage is a high-grade activated coconut carbon block pre-filter. The carbon block matrix enables maximum surface area and contact time, taking the first hit to adsorb chemicals such as Chlorine (which causes damage to the membrane), along with other harmful organic chemicals and contaminants. Keeping up with regular maintenance of this pre-filter (changing it every 6 months) is crucial to protecting and extending the life of all filters that come after it.

To maintain the optimum level of filtration year-round, and to ensure you get the maximum life out of your RO membrane (the engine room of this system), we strongly recommend a consistent filter maintenance schedule.

The pre-filters thus serve the dual purpose of blocking sediment particles larger than 5 microns and removing chlorine, which both cause damage to the inside of the RO membrane in different ways:

Sediment particles physically damage the fine internals, causing micro-tears that allow contaminants through to the "clean" side of the osmotic membrane, as well as blocking up the membrane which can cause the system to stop producing water and force an excessive amount of water to waste.

Chlorine that has been dissolved in water creates corrosive hypochlorous and hydrochloric acids, which dissolve the delicate RO membrane (via a process called "ring chlorination" which disrupts the hydrogen bonding between the membrane's polymer matrix) and allows contaminants to pass through to the "clean side". Because this process occurs gradually over time, most people don't notice the taste of contamination until they change their membrane!

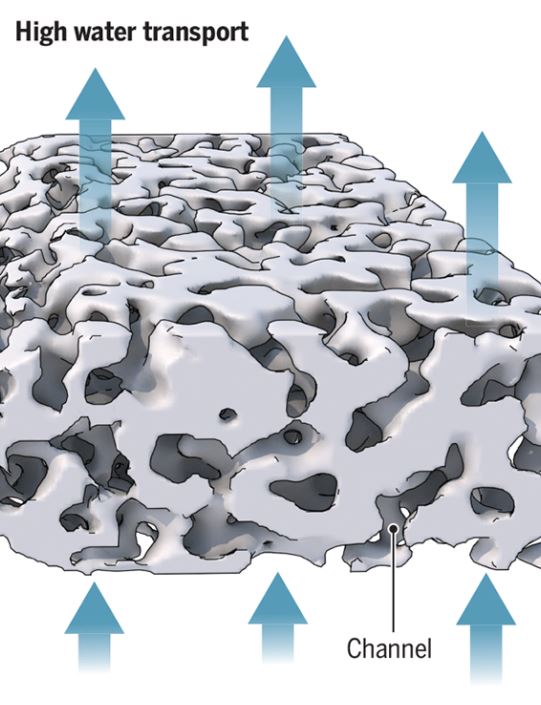

Reverse Osmosis membranes filter down to an ultra-fine level of filtration - down to 0.0001 of a micron - which is the reason why RO membranes can filter out minerals, salts, and metals (unlike carbon). Because this level of filtration is so fine, RO membranes do eventually clog up over time. How long you will be able to get out of your RO membrane, depends on the consistency of your membrane pre-filter maintenance, along with the starting quality of your water.

(Adapted from Geise, G.M., 2021, found in https://www.science.org/doi/10.1126/science.abe9741)

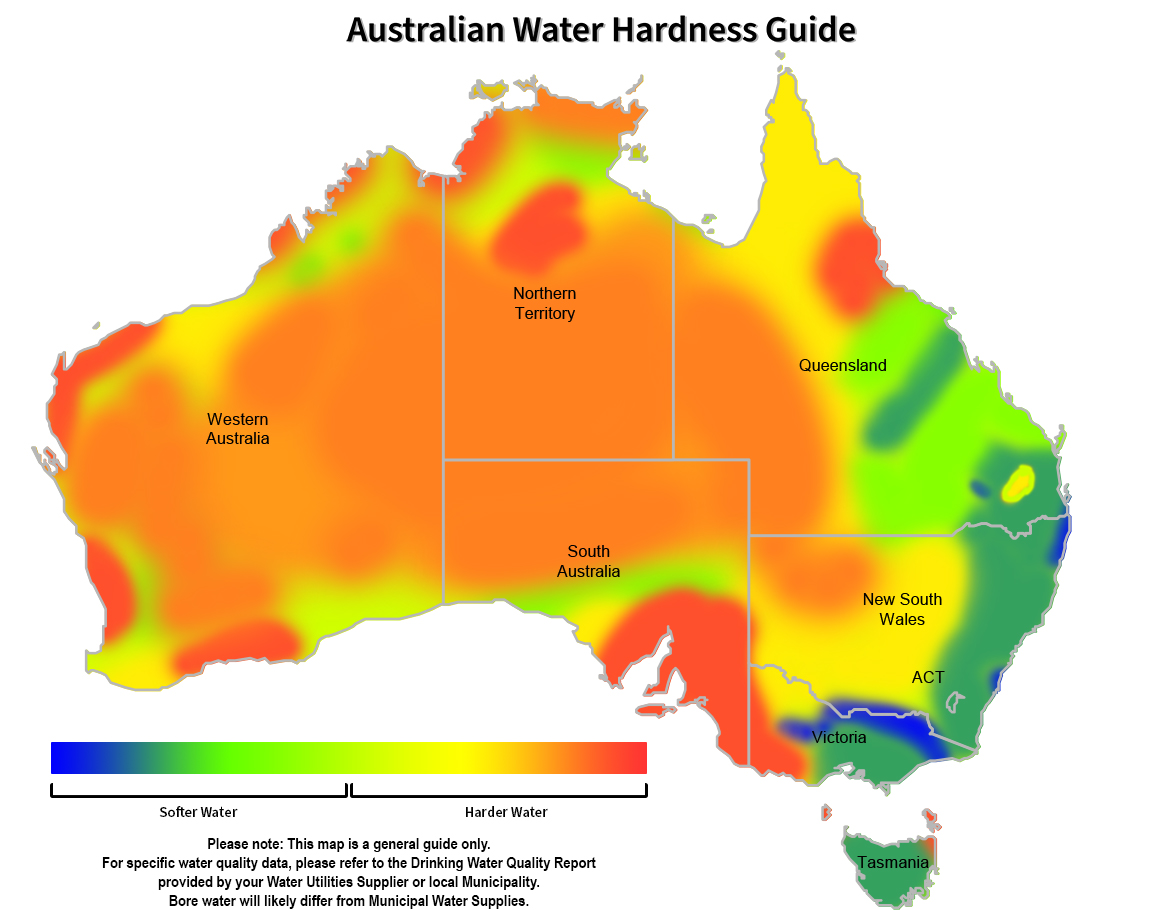

Western Australia, South Australia, the Northern Territory and Queensland tend to have hard water, along with those whose main source of water comes from a bore.

Thus, whilst we have specified a recommended maintenance schedule (below), the quality of the water in the area you live, is ultimately what will determine how long you get out of your RO membrane.

*If you are on hard water, at the 2-year mark, simply go for the FULL Replacement Pack (which includes an RO Membrane). Note - cases of extremely hard water may get less than 2 years out of an RO membrane.

These are all filters that go after the RO membrane to buffer the pH back up from an acidic state to an alkaline state, and "perfect" the water for final consumption. Over the course of a year, the diffusion of the alkalising minerals into the water will significantly diminish, whilst the carbon post-filter will eventually exhaust its capacity to adsorb residuals.

Recommended Tools Required:

Before changing filters, we recommend taking a photo of the system from various angles, then one by one, changing the cartridges. This will help you remember the orientation and flow direction of the filters and will save you time as opposed to trying to put the filter back together from scratch.

Shutting off the water: There are 3 things you need to do in this step.

Firstly, locate your inlet tee valve which connects water to your system, and shut this off by turning the tap 90°.

Secondly, you will need to shut off the storage tank valve located on top of the storage tank.

Finally, to relieve pressure in the system, open the drinking water faucet tap on the sink.

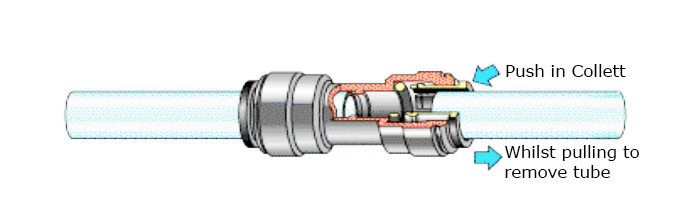

Disconnecting the System: To make things easier, we recommend disconnecting the system and performing the filter change over the sink, rather than trying to do the filter change in a hard-to-reach place such as under the sink. We also recommend laying down some towels to mop up dripping water from the lines when you disconnect the system. The four points you need to disconnect are:

1. The Storage Tank at point 12 (we recommend detaching this via the tee fitting connected to the T300 Hydrogen Rich Filter);

2. The Inlet Water at point 4A (this should be disconnected at the inlet to the system ie. the elbow plugged into the Stage 1 Dirt/Sediment Filter);

3. The Drain Line at point 10 (leave the Flow 200 Flow Restrictor connected to the RO membrane by the black tube in its original position), and finally;

4. The Carbon Post-Filter at point 4C (disconnect tubing from the last inline carbon post-filter, which leads to the faucet tap).

When this has been completed, you can then remove the system from under the sink and begin servicing it on the sink.

Due to the nature of the products we sell, a strict return policy is in place. We work with food grade certified materials that must be un-opened and un-used as to be able to be re-sold.

You may receive a refund or credit of equal amount, less the restocking fee if applicable and any other deductions that are relevant.

If you have any questions about our return policy, please contact us before purchase. This will also help to ensure you purchase the correct product that suits your requirements.